From time to time I get asked what else did Meadows do other than the Frisky?

In truth, the Frisky was only a very small part of Meadows, who made engines and gearboxes for multiple uses all over the world such as Cars, Lorries, Coaches, Boats, Combined Harvesters, Tractors, Compressors, Generators, Army tanks, trains and so on, too much to list.

The following article was originally written for The Bean Car Club magazine to give them some background about the company that made engines for them.

The Company was born on the evening of Tuesday 15th April 1919, at a meeting of a group of Wolverhampton businessmen. This meeting was held in the Little Swan Hotel, Horseley Fields, and a resolution was passed establishing the name of the Company as Henry Meadows Ltd; the registered Offices, for the time being, were Carlton Chambers, Lichfield St Wolverhampton, these being the offices of a solicitor.

A well known Wednesfield Manufacturer, Mr S H Ellard was appointed Chairman and Mr Henry Meadows was appointed Managing Director as from the time when the factory was erected. Mr Meadows had previously been Works Manager with the Clyno Engineering Company (1917),The National Fuse Factory Tipton (1917 to 1919).

The object of the Company was to manufacture, by mass production methods, gearboxes, and in particular 4-speed gearboxes, the need for which was becoming apparent due to the development of engines with a greater range of power.

Arrangements were made for the building of the First portion of the Park Lane Factory, consisting of a machine shop of four bays and a fitting shop, which included Office, hardening shop and stores. Later on, an ex-army hut was purchased for use as offices, and this was on Boswell's Field where it eventually became a paint shop.

In September 1919, the then Mayor of Wolverhampton Councillor A G Jeffs was appointed a Director of the company and in June 1920 he took over the Chairmanship and in later years his son Mr A W Jeffs also joined the board. Henry Meadows succeeded Mr A G Jeffs as Chairman in January 1936

The first gearbox, which was for a Vulcan lorry was produced in May 1920. It was a 3-speed box with reverse, and as far as can be ascertained, the price was ?25.00.

From the early records of the Company, it is evident that the Vulcan Engineering Company was Meadows first main customer. They were certainly the principal customer through the remainder of 1920 although in 1921 other well known names begin to appear such as The Equipment and Engineering Company, The Coventry Motor Car Company and the Coventry Simplex Engine

In August 1921, Mr John E Dorman, an engineer skilled in the production of internal combustion engines, who had previously been with the family business of W H Dorman of Stafford, was appointed a Director, and the Company then decided to commence the manufacture of engines, finding that many of the smaller car manufactures then in existence preferred to buy the engine and gearbox as one unit.

At the same time, Mr R S Crump (who later went on to become responsible for the majority of the Meadows Engines) came into the organisation as Chief designer along with a number of other specialists who immediately started on the design and production of the company's first petrol engine, an overhead valve four cylinder 63 x 120mm which was exhibited in the 1922 Motor Show production was about 8 to 10 engines per week.

One of the most popular of the early Meadows engines was the 11/2 litre four-cylinder type 4ED 50bhp, widely used by Frazer Nash and Lea Francis from 1926 during the "twenties"as well as by about a dozen of the smaller firms of car manufacturers. The names of many famous racing drivers were associated with the Meadows engine during this period, including Kaye Don, who gave a spectacular performance in a blown Meadows engined Lea Francis to win the 1928 Ulster T.T. event.

Considerable success also came to the 41/2 litre six-cylinder type 6ESC engine, a larger model which was introduced soon afterwards, and is best remembered as the power unit for Invicta and Lagonda cars. Raymond Mays (with his specially prepared Invicta 145bhp on petrol and 158bhp on alcohol!)and other stars of the race track made these cars famous. A Meadows powered Invicta won the Monte Carlo Rally in 1931, and it was not until after the war that a British car was again able to take first place. This engine survived from 1925 to 1939 a tribute to its design in the face of advancing mechanical and metallurgical techniques.

Perhaps even more notable was the success of the 4 ELA model, produced for Guy Motors for commercial vehicle work. Many thousands of these engines were on the road, and they were adopted for a wide range of applications such as driving pumps, welders and compressors.

Soon after their entry into the marine market, Meadows engines were attracting the same kind of attention among enthusiasts for high speed craft as the earlier engines had attracted in the sports car world. The 41/2 litre model was standardised in

Mr Hubert Scott-Paine's (the famous speed boat designer and record-breaker) high speed craft and soon British Power boats were winning world renown. Henry Meadows son, Henry Meadows Jnr, know as "Harry " to avoid confusion! worked with Scott-Paine in 1931 at The British Power Boat Company Hythe Southampton later returning to Meadows. Scott-Paine was a director of both Meadows and The British Power Boat Co.

In the early 1930's, under cover of great secrecy, a certain T E Shaw also worked with both Meadows and The British Powerboat, perhaps better remembered as "Lawrence of Arabia". He was involved in the development testing of big twin-engine boats developed at the Hythe. supplied to the RAF under Admiralty contract.

The Local paper The Express and Star reported that "he used the alias "T E Smith "

when signing the visitors book at the Victoria Hotel Wolverhampton but was recognised one night in the lounge by a man who had been in Arabia with him during the war, he then took refuge in a local coffee tavern where he stayed without revealing his name going each day to the Meadows works" They also commented that owing to the national importance of the work carried out at the factory few details have ever been divulged.

Henry Meadows secured in 1933 a first sanction to the value of ?120,000 on one of the biggest contracts ever received by a British firm, at that time, from a foreign motor car manufacturer . This had been the result of several months negotiations with one of the biggest motor car firms on the continent and the contract was obtained in the face of severe competition with other producers of engines and gearbox units both in this country and abroad.

In July 1937 news of the sudden death of the founder Henry Meadows at the age of 57 rocked Wolverhampton. "He was the head of one of the most important undertakings in the Midlands which employs hundreds of hands and which has for some time been performing work of great national importance" stated the Express and Star reporting his funeral. The coffin was borne into the church by six bearers drawn from the works and staff, employees flanked the footpath and pathway leading to the doors of the Church at St Phillips Penn Fields Wolverhampton along with mourners from many local and national businesses.

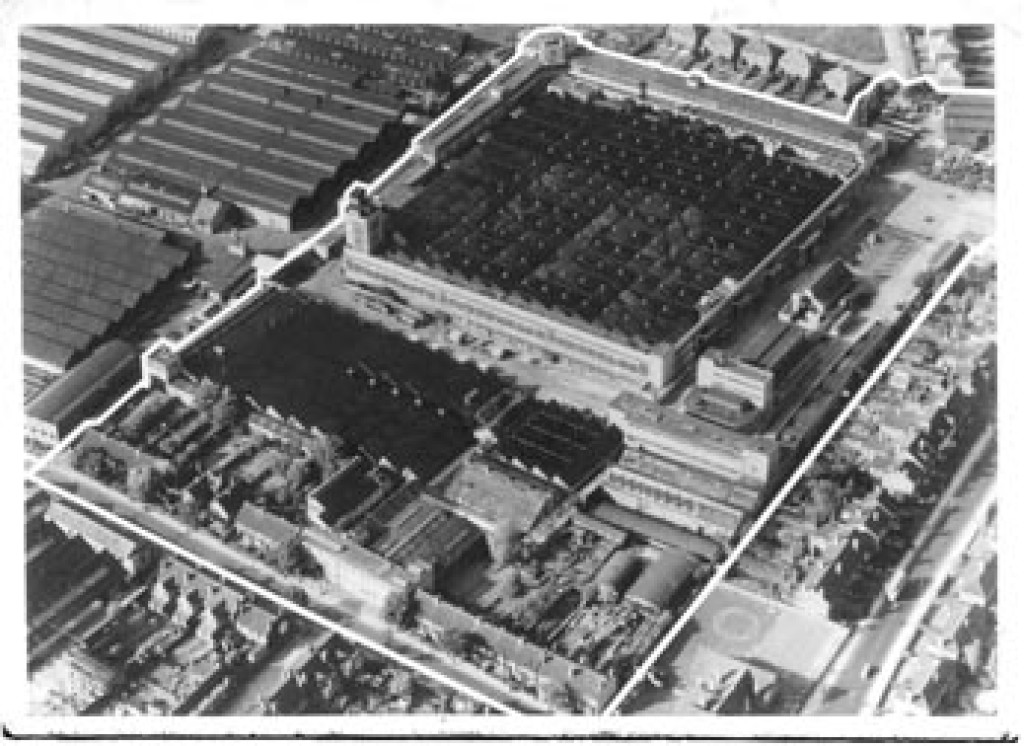

By 1938 Meadows had firmly established itself, and the works at Fallings Park now covering 16,000 square feet were working at full capacity.

Engines similar to those used in high-speed marine craft were being used in the

Mark VI Vickers Carden-Lloyd tracked vehicles, and as Britain moved into the early war years, steps were taken for Meadows engines to play a leading part in winning the war, as they had led in the years of development which had gone before.

The close collaboration which had been built up with the Mechanisation Department of the War Office since 1927 had led to the development of a 200h.p. 12 cylinder horizontally opposed petrol engine and works extensions were undertaken to facilitate production. In 1939 came demands for a 300h.p. engine on similar lines, and within six months a prototype was built, tested and approved. Several thousands of these type DAV 16,204cc engines were used to power Covenanter tanks, Bovington Tank museum Dorset holds many examples also including the smaller 12 cylinder MAT/1 8,858cc engine used in the Tetrarch light tank.

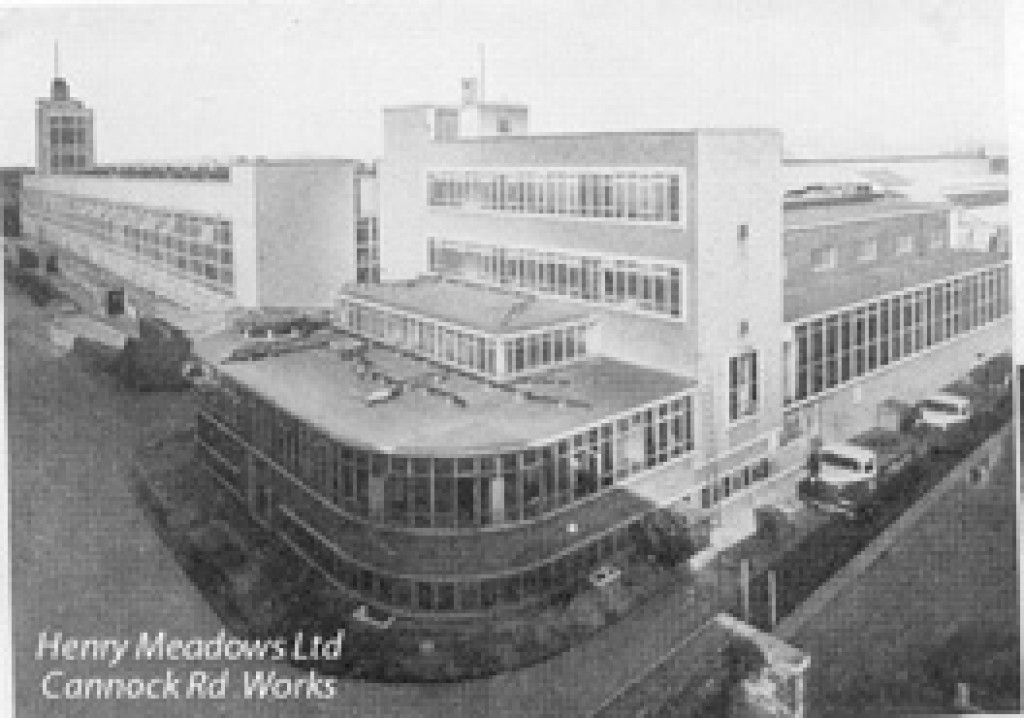

To meet growing war-time demands a new factory (the Cannock Road factory) was erected alongside the old works in Park Lane. The new buildings equipped with the latest machine tools, and adding 430,500 square feet to production capacity, rank as one of the finest factories in the Midlands at that time.

These improvements enabled Meadows to add a stirring chapter to its history by the production of high powered engines which played a major part in Britain's war effort, and helped to carry British arms to victory in many theatres. Apart from tank engines and transmissions, generating sets, commercial vehicle engines, trailer pumps and other smaller equipment were turned out at Fallings Park.

Meadows output continued to expandv rapidly with the result that their engines were used troughout the world, particularly in the commercial vehicle industry, for heavy specialized equipment.

Soon after the end of the war Meadows stepped into a different peace time market with a new development, the now well known four and six cylinder direct injection diesel engines of 130m.m. bore and stroke, which proved conclusively that it was possible to obtain, with a "square" bore/stroke ratio, a specific fuel consumption as good as that of the established long stroke engines. An added advantage was that, with its low piston speed, this type of engine showed a marked reduction in wear.

This entry into the diesel engine field was made possible by experiments which were started immediately before the war. On a reduced scale, experiments continued during the war, so that production of this type of engine could be started with the minimum of delay

The days of the small car firms who bought engines and other special components for assembly were now a thing of the past and Meadows products were mainly used in the commercial world and in heavy equipment such as oil field engines. An effective use of the heavier Meadows Commercial vehicle engine being in the Scammell tank recovery vehicle.

Following a brief period with The Bush Aboe Group, in 1952 Meadows became part of the Associated British Engineering Group. Producing engines for use in a wide range of markets. Apart for their better known use in commercial vehicles such as Scammell, ERF, Dodge etc, they were also supplied across the world for use in Coaches, Trains, Buses, light boats, trawlers tractors and combined harvesters. Their stationary engines powered particularly diverse applications such as Power generators, compressors, alternators, pumps, oilfield equipment, rock crushers and were renown for their reliability

A Meadows generating set was used by the 1957 British Antarctic expedition, upon contacting the expedition to check on its performance the engineers were told. "We haven't seen it for over 10 days! its buried in deep snow, we just keep pouring diesel down the feed pipe and exhaust fumes come out of the other, so yes its doing a great job!"

Also the two generators used for the Nuclear tests at Maralinga Western Australia survived an explosion described as "no more powerful than a few tens of thousands of tons". Although superficially damaged they were easily started immediately after the explosion.

In 1955 Meadows entered an entirely new area "Micro car Production" Raymond Flower an international racing driver approached Meadows with the idea of producing their own light weight car and by 1956 a prototype had been built and tested.

Launched at the 1957 Geneva Motor show it was called "The Meadows Frisky" the original Gull winged car was designed by Giovanni Michelotti and built by Vignale of Turin. It caused a sensation but problems with the doors made it too expensive to produce. In September the car was re-launched at the 1957 Earls Court show as

"The Meadows FriskySport" (Fibre glass body, tubular ladder chassis, Villiers 325cc twin engine) it enjoyed a brief success along with other Microcars but they were eventually over taken by the Mini. In the early 1960?s

In 1965 Jaguar Cars Ltd who already owned Guy motors purchased Meadows from Kidlington Securities and Quinton Hazell Colwyn Bay. Their stated intention was to use Meadows to augment the existing manufacturing facilities for the

Jaguar-Cummins diesel engine for which they anticipated a large demand. Hopes were high that Meadows had finally fallen on its feet but unfortunately it just never happened, they later became part of Leyland and the factory went into decline and so the once great Midland Company ground to a halt..

The factory has all now gone with the exception of a couple of the old buildings The famous Tower building was finally demolished in the late 1990's now being replaced by Industrial units.

But there are still Midland folk who talk with affection about working at the Medus!

I would be very pleased to hear from any body with information, experiences or even anecdotes of the Meadows Factory, people or products.

Henry John Meadows July 2012